Category: Plastics Manufacturing Equipment

Top 10 Largest Plastic Producing Companies

Epoxy: Manufacturing Process & Applications

Epoxy is a class of thermosetting resin derived by the polymerization of epoxides. It is capable of forming tightly linked cross-polymer structures, and can be either made into an adhesive or cured to form high-strength polymers. Its areas of application range from Construction to Aerospace. Manufacturing Process Epoxy resins can[…]

Thermoplastics & Their Applications

Thermoplastics are polymers that become mouldable upon application of heat and solidify upon cooling, without undergoing any disintegration of molecular structure or mechanical properties. Acrylic, ABS, nylon, PLA, polyether sulphone, polyether ether ketone, polyetherimide, polyethylene, polyphenylene oxide, polyphenylene sulphide, polypropylene, polystyrene, polyvinyl chloride, and Teflon are some of the most[…]

Best Techniques To Produce Plastic Products

Factors which Impact the Plastic Parts Design

Designing of a product is an integral aspect in the Plastics industry. There are a variety of ways through which plastics can be designed and this is usually decided before the commencement of the manufacturing process. One of the popular methods is the injection molding process Injection molding process has[…]

A Brief Guide on the Types of Injection Molding

Plastic Injection Molding is a manufacturing process that produces plastic parts by injecting materials into the mold. It is a swift process for producing plastic items in large numbers. Some of the merits of this method when compared to any other process; is that it is accurate, flawless, reasonable price,[…]

Know more about Recycled Polypropylene

Polypropylene is always cited as the polymer of future. There is a growing demand for recycled polypropylene in various industries, according to the latest survey conducted by the Association of Plastic Recyclers. Recycled Polypropylene (PP) Polypropylenes are plastics polymers that are members of the ‘polyolefin’ family. It is a highly[…]

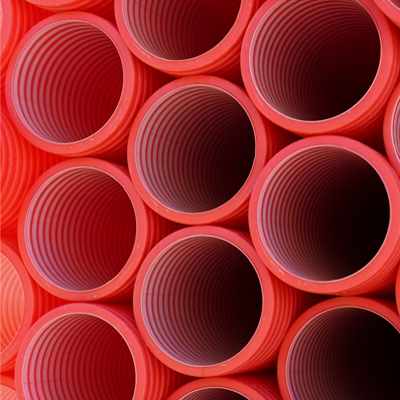

Trenchless Applications & Trenchless Construction Options For UPVC Pipe Fittings Exporters in India

UPVC fittings with triple advantages – Lower cost, proven durability and corrosion resistant. UPVC pipe fittings are considered superior choice for trenchless installations and they are manufactured wisely to suit the variety of applications worldwide like water supplies, gas supplies or chemical storage etc. They can be quickly connected to[…]

5 Ways to Optimize your Thermoforming Operations to Restore Performance

Modernization of Equipment- Are you looking at your thermoforming equipment, wondering if there could be a better way to get more out of them? Are you noticing subtle reductions to your output? How long have you owned your machines? Although the process of thermoforming has been around for a long[…]

Special Purpose Forming Machines | PlasticS Industry

Global Thermoformers’s is the designer and manufacturer of Automatic thermo forming machines and equipments with specialty in the packaging solutions. It manufactures an extensive range of Automatic thermo forming machines for thin wall applications or thick wall application, plastic packaging & compact sheet line extruder machinery. The Special purpose forming machines[…]

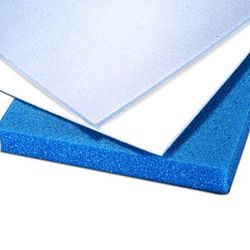

PP Flute Boards or Polypropylene Flute Sheets

Vinayak Plastic Industries’s is engaged in manufacturing and exporting of PP Flute Boards. The company was founded in the year 2005 by Mr. Kamlesh Joshi who is the owner of at Dadra & Nagar Haveli company of India. The PP Flute Boards are also called as Polypropylene Flute Sheets which are designed[…]

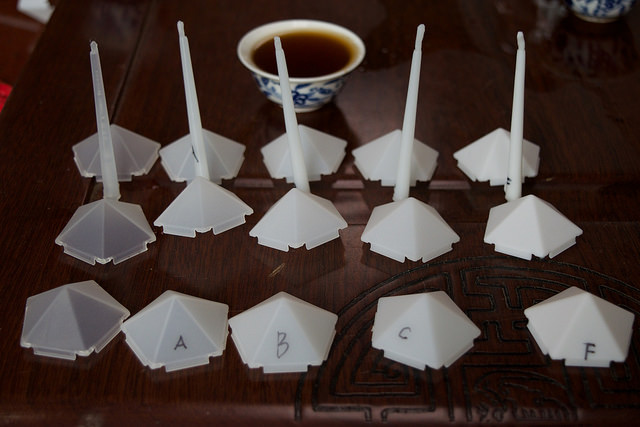

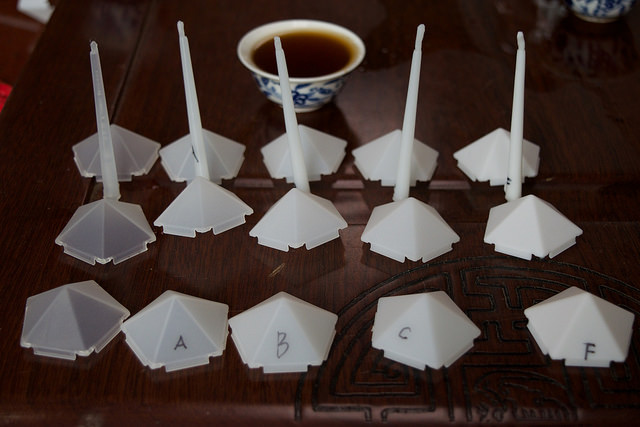

5 Things to Look Out for in Plastic Prototyping

A great way to determine if your part will function as designed is by creating a prototype. Prototypes have the amazing ability to transform your work into something tangible and make your idea come to life. Plastic prototyping has opened up a whole new world of possibilities. Unlike previous methods[…]

Plastic Pipes – How It is Continually Re-Shaping Global Construction Markets

In a world fighting with years’ old infrastructural foundation and more successive critical climate changes while additionally looking for more sustainable and energy efficient building results — polymer-based materials are taking up a greater amount of the load. From bridges and streets to material and structures, inventive structures are utilizing[…]

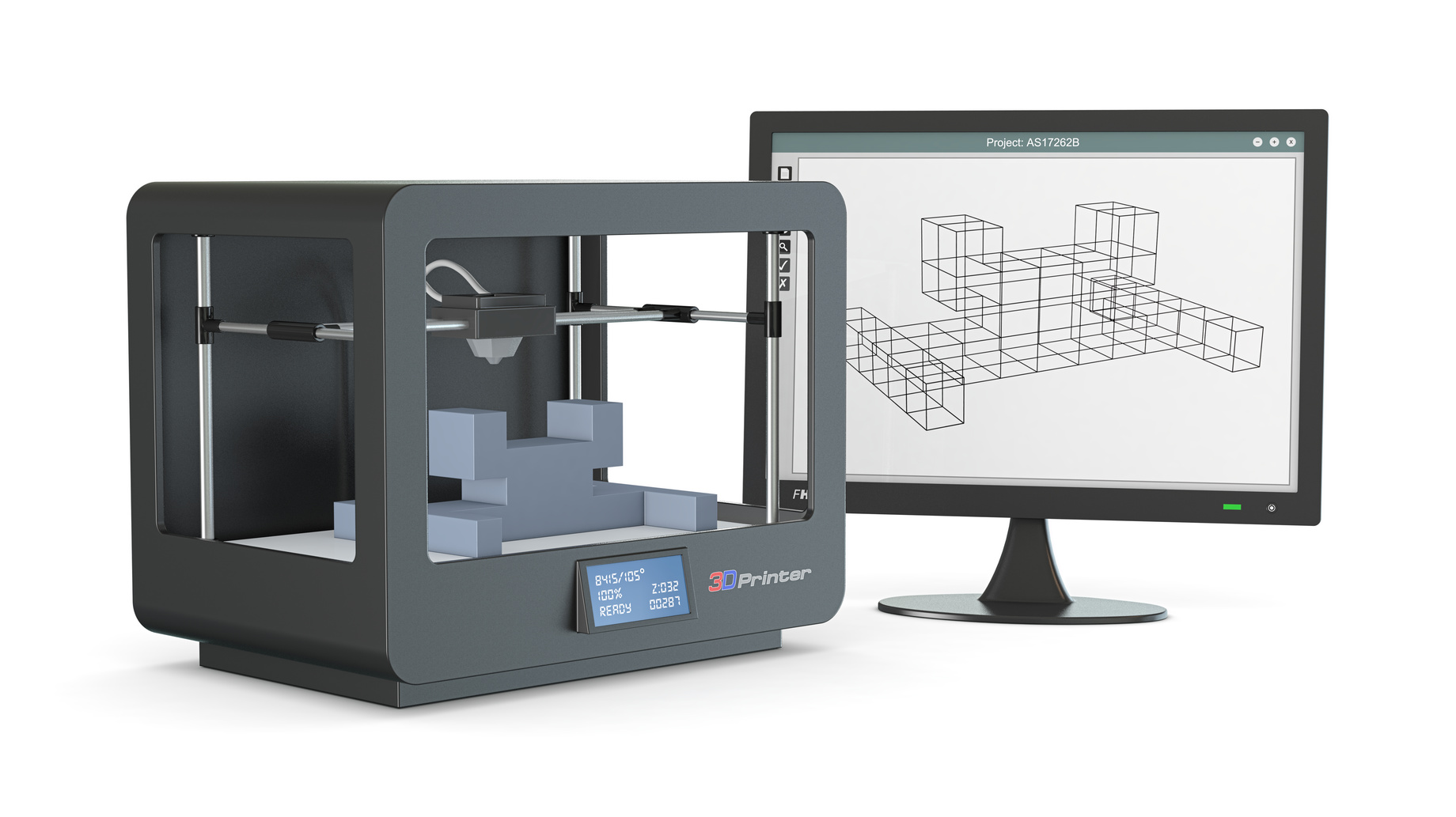

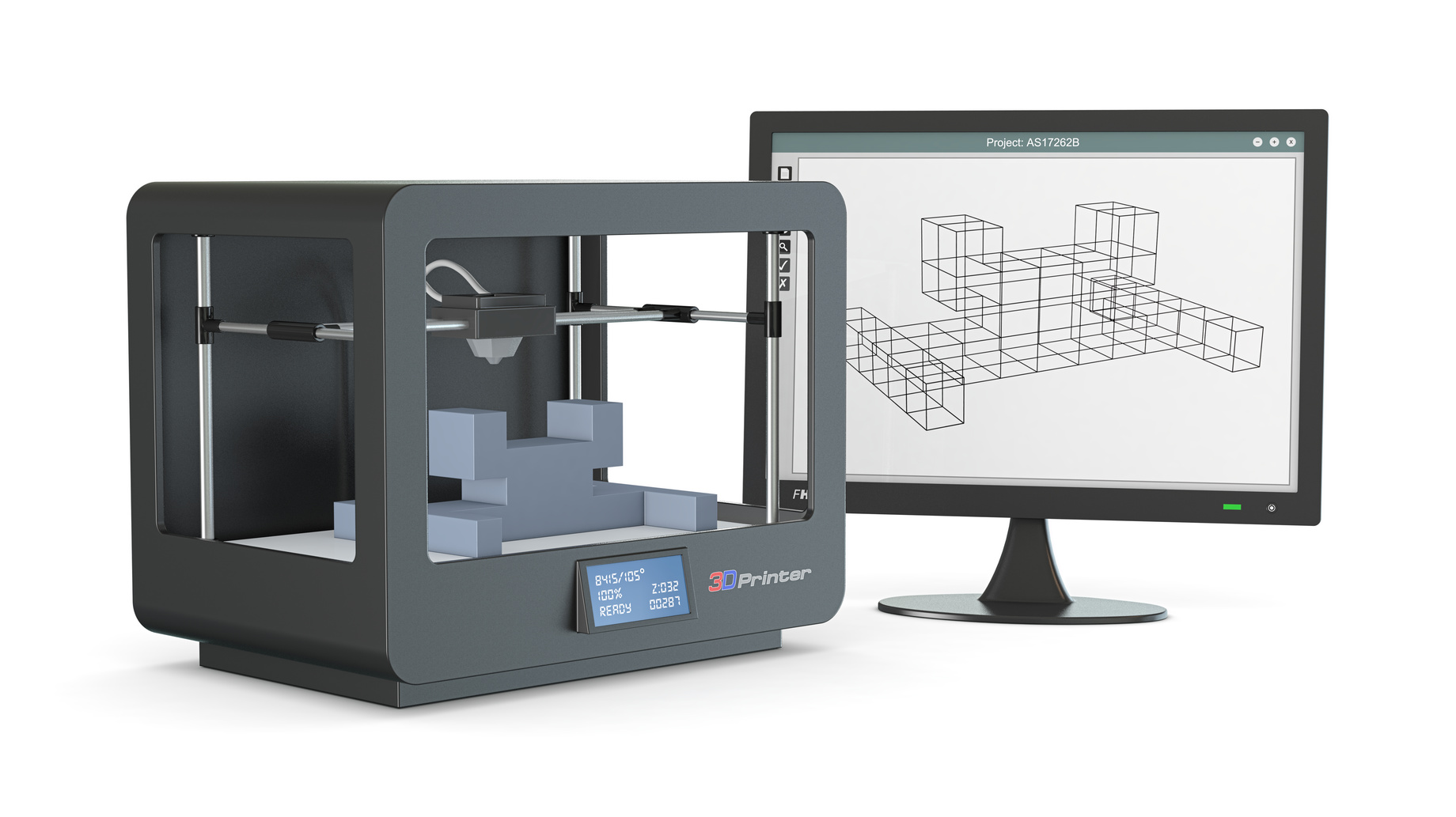

The CAD CAM revolution in the Plastics industry

New innovation is continually energizing yet not generally reasonable. How frequently has an apparently as good as ever contraption hit the market that your wallet basically hasn’t had the capacity to stomach? Since the early improvement of SKETCHPAD in 1963, an ancestor of CAD and CAM programming, the issue has[…]

Melt-Flow Rate Testing

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number. Melt indexers, or extrusion plastometers, are common lab tools used to[…]

Microcellular Foam – The Next Step From Cellular

Technology changes every day. Even in the world of plastics there is continual research and development to arrive at newer and fresher alternatives. In the light of the same, microcellular foam is a breakthrough technology in the plastics industry. The concept or the technology of microcellular thermoplastic foam appears to[…]

Wood-Plastic Composite

Though not a recent phenomenon, wood-plastic composites is posing to be a much sought after and compelling realm within the plastics industry. Also, there is a continually maturing interest in the new design potentialities that this amalgamation of components used, has to offer. It is, at its heart, a composite[…]

Injection Moulding Climbs the Ladder

Injection molding is unanimously the core process in plastic equipment manufacturing industry. As in any industry sector, the present techniques and technologies used in manufacturing process deserve promotion in terms of every aspect including energy efficiency, output quality, processing time, reliability of usage and ease of operation. Being the core[…]

Revolution on Plastics Outgassing

Over 2.5 million water bottles are thrown away every HOUR in United States alone and this statistics doesn’t include thousands of other plastic products that are manufactured, used and discarded at the same time. If these calculation results are consolidated, the plastic waste would be beyond 60 billion tons every[…]

Top 10 Largest Plastic Producing Companies

Epoxy: Manufacturing Process & Applications

Epoxy is a class of thermosetting resin derived by the polymerization of epoxides. It is capable of forming tightly linked cross-polymer structures, and can be either made into an adhesive or cured to form high-strength polymers. Its areas of application range from Construction to Aerospace. Manufacturing Process Epoxy resins can[…]

Thermoplastics & Their Applications

Thermoplastics are polymers that become mouldable upon application of heat and solidify upon cooling, without undergoing any disintegration of molecular structure or mechanical properties. Acrylic, ABS, nylon, PLA, polyether sulphone, polyether ether ketone, polyetherimide, polyethylene, polyphenylene oxide, polyphenylene sulphide, polypropylene, polystyrene, polyvinyl chloride, and Teflon are some of the most[…]

Best Techniques To Produce Plastic Products

Factors which Impact the Plastic Parts Design

Designing of a product is an integral aspect in the Plastics industry. There are a variety of ways through which plastics can be designed and this is usually decided before the commencement of the manufacturing process. One of the popular methods is the injection molding process Injection molding process has[…]

A Brief Guide on the Types of Injection Molding

Plastic Injection Molding is a manufacturing process that produces plastic parts by injecting materials into the mold. It is a swift process for producing plastic items in large numbers. Some of the merits of this method when compared to any other process; is that it is accurate, flawless, reasonable price,[…]

Know more about Recycled Polypropylene

Polypropylene is always cited as the polymer of future. There is a growing demand for recycled polypropylene in various industries, according to the latest survey conducted by the Association of Plastic Recyclers. Recycled Polypropylene (PP) Polypropylenes are plastics polymers that are members of the ‘polyolefin’ family. It is a highly[…]

Trenchless Applications & Trenchless Construction Options For UPVC Pipe Fittings Exporters in India

UPVC fittings with triple advantages – Lower cost, proven durability and corrosion resistant. UPVC pipe fittings are considered superior choice for trenchless installations and they are manufactured wisely to suit the variety of applications worldwide like water supplies, gas supplies or chemical storage etc. They can be quickly connected to[…]

5 Ways to Optimize your Thermoforming Operations to Restore Performance

Modernization of Equipment- Are you looking at your thermoforming equipment, wondering if there could be a better way to get more out of them? Are you noticing subtle reductions to your output? How long have you owned your machines? Although the process of thermoforming has been around for a long[…]

Special Purpose Forming Machines | PlasticS Industry

Global Thermoformers’s is the designer and manufacturer of Automatic thermo forming machines and equipments with specialty in the packaging solutions. It manufactures an extensive range of Automatic thermo forming machines for thin wall applications or thick wall application, plastic packaging & compact sheet line extruder machinery. The Special purpose forming machines[…]

PP Flute Boards or Polypropylene Flute Sheets

Vinayak Plastic Industries’s is engaged in manufacturing and exporting of PP Flute Boards. The company was founded in the year 2005 by Mr. Kamlesh Joshi who is the owner of at Dadra & Nagar Haveli company of India. The PP Flute Boards are also called as Polypropylene Flute Sheets which are designed[…]

5 Things to Look Out for in Plastic Prototyping

A great way to determine if your part will function as designed is by creating a prototype. Prototypes have the amazing ability to transform your work into something tangible and make your idea come to life. Plastic prototyping has opened up a whole new world of possibilities. Unlike previous methods[…]

Plastic Pipes – How It is Continually Re-Shaping Global Construction Markets

In a world fighting with years’ old infrastructural foundation and more successive critical climate changes while additionally looking for more sustainable and energy efficient building results — polymer-based materials are taking up a greater amount of the load. From bridges and streets to material and structures, inventive structures are utilizing[…]

The CAD CAM revolution in the Plastics industry

New innovation is continually energizing yet not generally reasonable. How frequently has an apparently as good as ever contraption hit the market that your wallet basically hasn’t had the capacity to stomach? Since the early improvement of SKETCHPAD in 1963, an ancestor of CAD and CAM programming, the issue has[…]

Melt-Flow Rate Testing

Though often criticized, MFR is a very good gauge of the relative average molecular weight of the polymer. Since molecular weight (MW) is the driving force behind performance in polymers, it turns out to be a very useful number. Melt indexers, or extrusion plastometers, are common lab tools used to[…]

Microcellular Foam – The Next Step From Cellular

Technology changes every day. Even in the world of plastics there is continual research and development to arrive at newer and fresher alternatives. In the light of the same, microcellular foam is a breakthrough technology in the plastics industry. The concept or the technology of microcellular thermoplastic foam appears to[…]

Wood-Plastic Composite

Though not a recent phenomenon, wood-plastic composites is posing to be a much sought after and compelling realm within the plastics industry. Also, there is a continually maturing interest in the new design potentialities that this amalgamation of components used, has to offer. It is, at its heart, a composite[…]

Injection Moulding Climbs the Ladder

Injection molding is unanimously the core process in plastic equipment manufacturing industry. As in any industry sector, the present techniques and technologies used in manufacturing process deserve promotion in terms of every aspect including energy efficiency, output quality, processing time, reliability of usage and ease of operation. Being the core[…]

Revolution on Plastics Outgassing

Over 2.5 million water bottles are thrown away every HOUR in United States alone and this statistics doesn’t include thousands of other plastic products that are manufactured, used and discarded at the same time. If these calculation results are consolidated, the plastic waste would be beyond 60 billion tons every[…]