Technology changes every day. Even in the world of plastics there is continual research and development to arrive at newer and fresher alternatives. In the light of the same, microcellular foam is a breakthrough technology in the plastics industry.

The concept or the technology of microcellular thermoplastic foam appears to be an interesting extension of the cross-linked polyethylene foam. Nonetheless, its advantages and recent developments have spurred many commercial uses. Given the uniqueness of the technology, the breadth of application is continuing to grow and the future has practically no limits.

Microcellular thermoplastic foam came to the public in the eighties from MIT, unique in its cell size (100 – 101 microns) to differentiate from the conventional cellular products with cell size ranging from 102 to 104 microns. It employs inorganic physical blowing agent in its supercritical state to create a swarm of bubble in the polymeric matrix. In the midst of ozone depletion concerns, it soon caught public’s attention and support.

In ten years, it moved from batch mode to continuous process. When Trexel is formed to bring this microcellular thermoplastic foam or Mucell technology to plastics industry, it was clearly focused on the material instead of the product. It turned out to be a clever approach in licensing the Mucell technology to equipment suppliers as well as foam producers, quite promising in bridging the gap between polymeric materials and polymeric foam products.

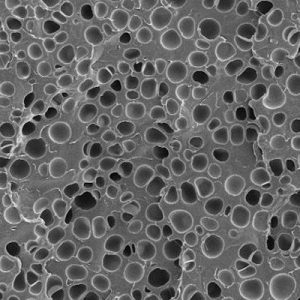

The unique features of microcellular foam (MCF) are fine cell size, high cell density, inorganic blowing agent, and no nucleating agent. Since the cell is very fine, without careful attention, MCF may be taken as a plastic material rather than a cellular product.

The unique features of microcellular foam (MCF) are fine cell size, high cell density, inorganic blowing agent, and no nucleating agent. Since the cell is very fine, without careful attention, MCF may be taken as a plastic material rather than a cellular product.

When cell is reduced to micron range without using nucleating agent, decreased convection in the cell and less open cell make a uniform structured product with better insulation characteristics. Some mechanical properties, especially propagation related; such as: notch and fatigue, appeared superior to the parent plastic material. It was attributed to cell as propagation absorber. Conventional polymeric foam is known for its high performance/weight ratio, which increases as cell size decreases and cell integrity improves. This evidently enlarges property spectrum.

Foaming is a phase separation phenomenon governed by thermodynamic-driven kinetics. A common practice is to establish a positive super-heat, or super saturation, that volatile phase tends to conglomerate into spherical gas bubbles. In general, saturate with gas, then apply vacuum or heat, or both, to induce thermodynamic instability. Bubbles appear.

X-linked PE foam producers tempted compounding chemical blowing agent (CBA) into PE, and X-linking first to enhance polymeric strength, and then decompose the CBA to liberate nitrogen to form cellular structure. The less the expansion,the finer the cell. Fewer than ten times expansion, ten microns or under can be achieved. At thirty times expansion, the cell is in the hundred microns.

The conventional cellular foam (i.e. cell size in mm) is generally blown with non-volatile hydrocarbon blowing agent as opposed to microcellular foam with volatile carbon dioxide or nitrogen. The latter is characterized by aggressive, highly nucleated, and limited expansion in contrast to the former less aggressive, lowly nucleated, and large expansion. It was also noted that the cellular nucleation is heterogeneous in nature (i.e. adding nucleating agent), and microcellular homogeneous (i.e. without nucleating agent). Microcellular foam contains 108 cells/cm3, and cellular foam around 104 – 106 cells/cm3.

The aggressive expansion in microcellular makes the polymeric strength very critical in maintaining cell integrity, even more so in continuous extrusion, cell coalescence becomes otherwise inevitable. Thick cell wall is thus very necessary, and that lays the expansion limit to around ten times, whereas the cellular foaming can achieve over fifty times expansion. Saving materials can justify the material handling investment, therefore, cellular foam is still quite popular in the market.

However, when expansion reduces to 30 to 70% weight reduction, about two to three times expansion, quite a few polymers are qualified for processing and foaming. It became a great opportunity for engineered polymer, where material saving is rather substantial. Nylon, ABS, PC, and filled PP are good examples in MCF injection molding. Publications in methods and technologies can be found in references.

Predictions or Future Realities

When nano-particle becomes a great topic in enhancing polymer’s mechanical property, it is a natural combination into microcellular foam. Nano-particle could be an ideal nucleating agent, and even dispersion can generate interfacial volume as nucleus for microcellular morphology. This nano-microcellular polymer could be a great product with an impressive performance/weight ratio; excellent physical, mechanical and thermal properties.

The other challenge is to explore the finest cell size, highest cell density, and MCF density. Is nano-cellular possible? It will then be a pure material development.