In the vivid and complex realm of manufacturing, there’s an unsung hero that keeps the wheels of industry spinning – Computer Numerical Control, or CNC, machining. As an intriguing fusion of technology and craftsmanship, CNC machining has revolutionized manufacturing, especially when it comes to plastic materials.

Understanding CNC Machining

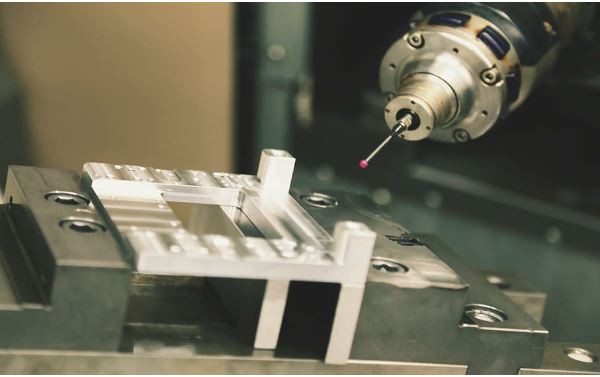

CNC machining refers to a subtractive manufacturing process where a computer controls the movement of cutting tools to shape a material, in this case, plastics. The CNC machine receives a digital file from a computer, interprets the design, and carries out the required actions. It can work with utmost precision, and even complex geometries can be executed without any error.

Unveiling the Cost Benefits of CNC Machining Plastics

In the panorama of CNC machining, plastics take center stage for several reasons. Here we explore the intriguing cost benefits of CNC machining plastics.

Reduced Material Wastage

One of the key cost advantages of CNC machining plastics is its propensity to minimize material waste. Traditional manufacturing methods, like injection molding, may leave a substantial amount of scrap material, which becomes a cost to dispose of or recycle. In contrast, CNC machining is a subtractive process that carves out the desired product from a solid block of plastic, leaving little to no waste.

Decreased Labor Costs

CNC machining also has the upper hand when it comes to labor costs. Unlike traditional manufacturing processes, which often require the presence and supervision of skilled labor, CNC machines can run autonomously. Once the design file is loaded and the machine is set up, it can continue to operate without constant human intervention, leading to substantial labor cost savings.

Economical for Small-Run Productions

For businesses that require low-volume or bespoke production runs, CNC machining offers a cost-effective solution. Unlike injection molding, which requires expensive mold creation, CNC machining can produce small batches at a reasonable cost, since it doesn’t require any upfront tooling costs.

Faster prototyping

Lower tooling costs

Economical for bespoke, unique, or small-volume orders

Extended Tool Life

Another economic advantage that is often overlooked is the extended tool life offered by CNC machining. Unlike metal, plastics are softer and easier on the cutting tools, resulting in less wear and tear and ultimately extending the lifespan of the tools used.

Empirical Evidence Supporting the Cost Efficiency of CNC Machining Plastics

Empirical studies support the cost benefits of CNC machining plastics. For instance, a study published by the Journal of Cleaner Production demonstrated that CNC machining plastics can reduce production costs by 25% to 50% compared to traditional methods1.

Breaking Down the Process of CNC Machining Plastics

To further appreciate the cost benefits of CNC machining plastics, it’s crucial to understand the process. So, let’s delve into the steps involved in this innovative technology.

Designing the Component

The first step in CNC machining is creating the design for the component to be produced. This is done using Computer-Aided Design (CAD) software, which enables the designer to create a 3D model of the part. The CAD software is a critical factor in controlling production costs because it reduces the time spent on designing and allows for the easy modification of designs.

Converting the Design into Machine Language

The CAD file is then converted into a language that the CNC machine can understand. This language, known as G-code, guides the machine on how to cut the plastic to produce the desired component. This conversion is carried out by Computer-Aided Manufacturing (CAM) software, which also contributes to cost efficiency by eliminating the potential for human error in the machining process.

Setting up the CNC Machine

Next, the plastic material is placed onto the CNC machine and the cutting tools are installed. The machine is then calibrated according to the specifications of the component. Once this setup is completed, the machine is ready to start machining.

Machining the Component

With everything set up, the CNC machine can now start the machining process. It follows the instructions in the G-code, cutting and shaping the plastic material with precision. This phase is highly efficient as the machine operates autonomously, requiring minimal human intervention.

The Broader Economic Implications of CNC Machining Plastics

The cost benefits of CNC machining plastics are not just confined to the manufacturing floor. This technology has broader economic implications that ripple through the entire industry.

Boosting Local Manufacturing

CNC machining has the potential to boost local manufacturing. By lowering the cost of production, businesses can compete with overseas manufacturers and stimulate local economies.

Driving Innovation

Moreover, the flexibility and affordability of CNC machining can foster innovation. Companies, particularly startups and small businesses, can experiment with new designs and products without worrying about high production costs.

Encouraging Sustainable Practices

The eco-friendliness of CNC machining, due to its low waste generation, can help companies embrace sustainable manufacturing practices. This, in turn, can reduce their environmental footprint and contribute to a green economy.

Conclusion

The cost benefits of CNC machining plastics permeate the entire production process and even extend to wider economic implications. With its ability to boost local manufacturing, drive innovation, and support sustainable practices, CNC machining emerges as a game-changer in the industry. Its popularity is a testament to the growing recognition of these benefits and the ever-increasing demand for cost-effective and efficient manufacturing solutions.

As the exploration of this topic continues, the cost benefits and the profound impacts of CNC machining plastics will likely continue to surface, offering a compelling reason for industries to adopt this technology. Therefore, CNC machining of plastics is not just a passing trend but a paradigm shift in the way we perceive and conduct manufacturing.