How does the injection molding process evolved in plastic industry?

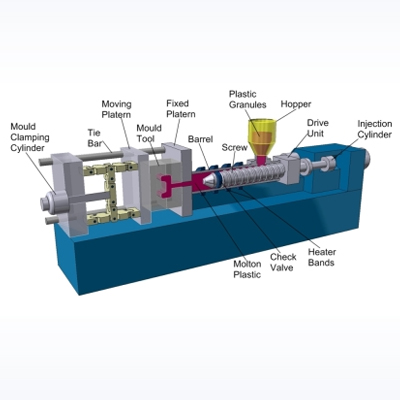

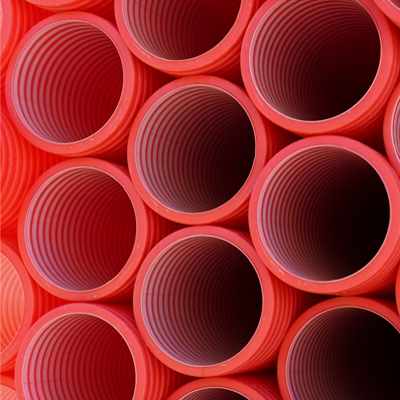

Plastic Injection molding is the manufacturing process for creating products using synthetic materials. In this process, the plastic is thrown into a heated barrel and is forced into a mold cavity where it loses the heat and hardens to the configuration of the mold cavity. The fascinating history of plastic injection[…]