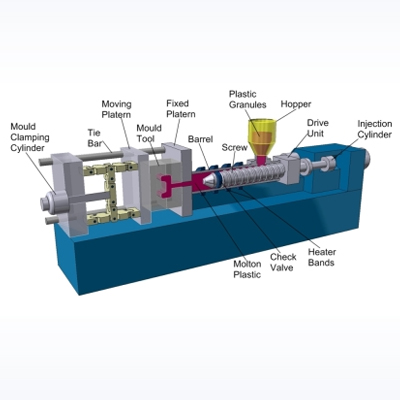

Know about Injection Molding Machinery

Fu Chun Shin’s is the manufacturer of Injection Molding Machinery. The HT-SV series implement high efficient motor and pump control technology. It is involved in high energy saving, high precise, high response, low noise and easy to be managed. When saving energy in ideal conditions, it saves around 40% when[…]