Polycarbonate is a very popular engineering plastic. It is used in several industrial and domestic applications. Its chemical and physical properties make it ideal for use in the fabrication of many useful products.

Polycarbonate manufacturers employ various techniques to achieve a variety of shapes and finishes. With the proper equipment, polycarbonate sheets are available in various sizes and thicknesses.

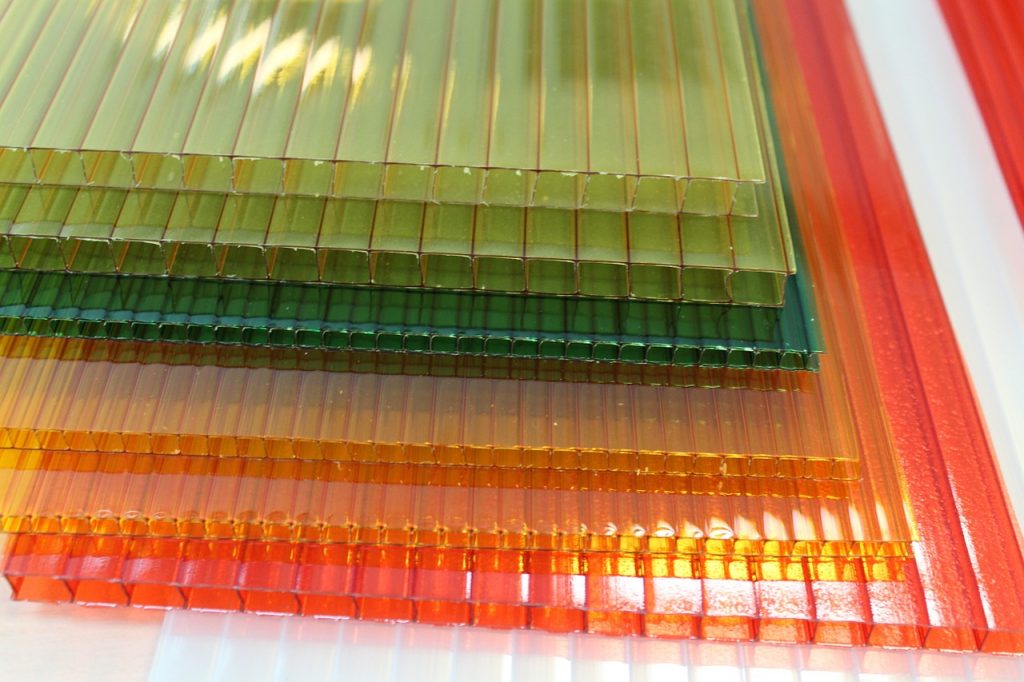

There are three classifications of polycarbonates.

1. Solid polycarbonate is available in sheets or panels that have excellent optical properties and very high impact strength.

2. Hollow polycarbonate has an air space grid between layers of polycarbonate sheets and is excellent for insulation.

3. Corrugated polycarbonate can be solid or hollow. They are shaped similarly to corrugated iron sheets.

Food containers are made with thin sheets of corrugated polycarbonate. Bulletproof windows, protective shields, and safety glasses are made with polycarbonate sheets. These essential products are manufactured using this type of plastic. Polycarbonate industrial tags and nameplates are used for an array of products. It is also very useful in building enclosures for swimming pools.

The physical properties that contribute to the usefulness of polycarbonate are:

Strength

PC sheets withstand very high impacts such as in used as hurricane barricades.

Transparency

Polycarbonates can transmit up to 99.99% of light visibility.

Dimensional Stability

PC is a rigid material that can withstand high stretching and compression.

Heat Resistance

Even at extreme temperatures, the PC will maintain its chemical and physical properties.

Electrical Resistance

Because of its molecular forces, PC acts as an insulator.

Self Extinguishing

Polycarbonate is UL94 classified and does not burn. This makes it an optimal choice for use in fire-prone conditions.

The customization of this material is done through the process of fabrication. To make the finished product, PC may be cut, bent, milled, thermoformed, or bonded. It can be finished with sanding and polishing and can also be printed.

Polycarbonate is something most people use or come in contact with daily. Polycarbonate sheets are commonly used as room dividers. Because it is so lightweight, it can easily be moved from one place to another. The room dividers can be manufactured in an accordion-style for ease in opening and closing. They can also be made a solid sheet on wheels so that it can be easily moved.

Electronics manufacturers utilize polycarbonate sheets in the construction of several devices. Because it is durable and lightweight, it works well for building laptops, smartphones, and other electronics that would be more sensitive to damage caused by impact.

Polycarbonate sheets can be great for the replacement of glass or acrylic in many instances. It is 200 times as strong as glass. Molding this material is also easier than molding other materials. It is often used for security light glazing and skylights. Because of its insulation properties, it can lower energy costs.

PC also provides UV protection. It has become increasingly popular in the construction of greenhouses. It provides warmth, light, and protection to plants while allowing in rays from the sun.

Sterilized polycarbonate is widely used in the medical industry. One of the top uses is manufacturing eyewear and medical supplies. Flexible tubes are used for blood or other fluids during procedures such as surgeries. The filter cartridges used in dialysis equipment are also made with polycarbonate. These are just two examples of how this material is used in the medical field.

The number of uses and products originating from polycarbonate is endless. It is a thermoplastic material that benefits our every day lives in numerous ways.